A Portable, Flexible Industry Solution

Engineered in Denmark, SoRoTo® Belt Conveyors have been the benchmark for portability and durability for more than 35 years. BISAF is proud to bring these industry-leading machines directly to UK customers, helping construction, logistics, and agriculture businesses work faster, cleaner, and more efficiently.

Lightweight Design Technology

SoRoTo® conveyors are the lightest belt conveyors on the market thanks to their open aluminium frame. This clever design keeps weight low without compromising strength, making the entire unit highly portable. Even the 8.0m model can be moved, set up, and operated by a single person, perfect for projects where flexibility and speed are critical.

Built for Any Task

SoRoTo® Belt Conveyors are available in five lengths — 2.0m, 3.3m, 4.5m, 6.0m, and 8.0m — with the 8.0m model unique to SoRoTo®. Built with a lightweight aluminium frame and a durable PVC belt, they are designed to handle almost any task on-site.

- Handles Almost Anything: Rubble, soil, gravel, concrete, wood chips, and more.

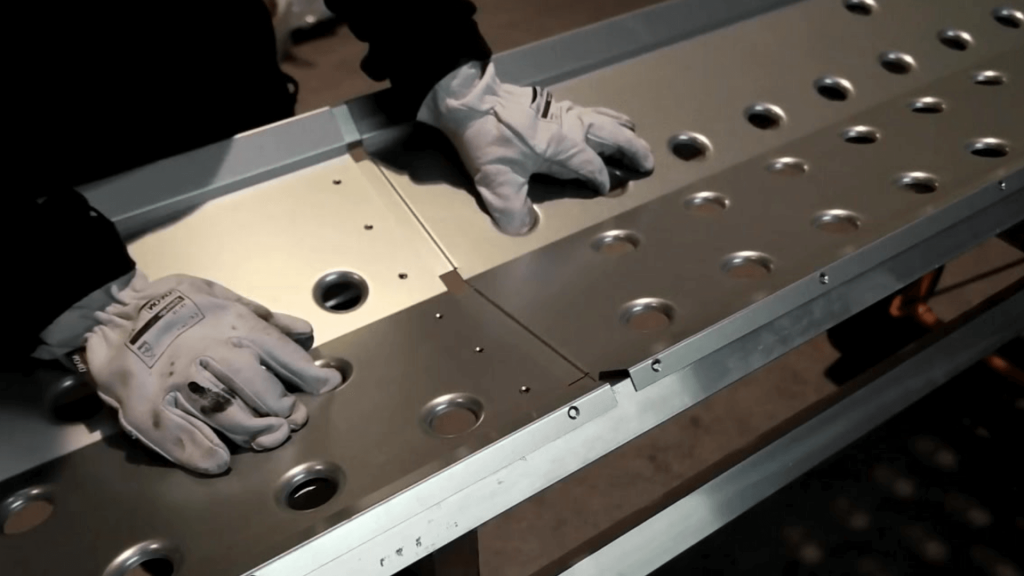

- Low-Maintenance Design: Self-cleaning steel plates cool and protect the belt.

- Modular Construction: Replace only the section you need, saving time and cost.

- Scalable & Flexible: Link multiple conveyors for longer runs or change direction.

- Adjustable Setup: Two-wheel undercarriage can be positioned anywhere to get the perfect angle.

Their clever open-sided design with perforated steel plates under the PVC belt means dirt and debris simply fall through during operation, creating a natural self-cleaning effect. The holes also allow the machine and belt to cool, reducing wear and keeping performance consistent over long shifts.

Optional accessories include a large infeed hopper for easy wheelbarrow loading and truck pockets to make moving conveyors around large sites fast and efficient.

The result? A durable, flexible, and highly portable conveyor system built for construction, logistics, and agriculture.

Lighten Your Workload with SoRoTo®

Switching from wheelbarrows or manual shovelling to a SoRoTo® conveyor saves time, reduces labour costs, and keeps projects moving. One operator can keep material flowing continuously, freeing up other team members for more productive tasks and creating a safer, cleaner working environment.

SoRoTo® conveyors are designed to grow with your project. Multiple units can be linked in series to extend reach or change direction, while the adjustable two-wheel undercarriage allows you to fine-tune the angle for your specific task.

Find Out More

Customise for your material

Every job is different and SoRoTo® Belt Conveyors are designed to adapt. Choosing the right belt is one of the simplest ways to customise your conveyor.

The standard belt comes with 10mm carriers, perfect for everyday material handling. For heavy or wet loads such as concrete, a smooth carrier-free belt keeps the flow consistent and prevents material from sticking. For light, loose materials like hay or wood chips, a belt with taller carriers gives extra grip and keeps everything moving efficiently.

With multiple belt options available, you can configure your conveyor for maximum performance, whatever the task.

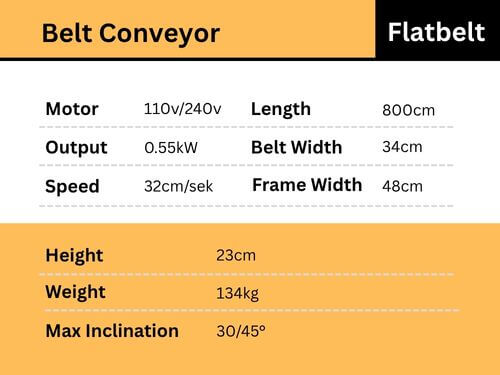

Conveyor Belt Specifications