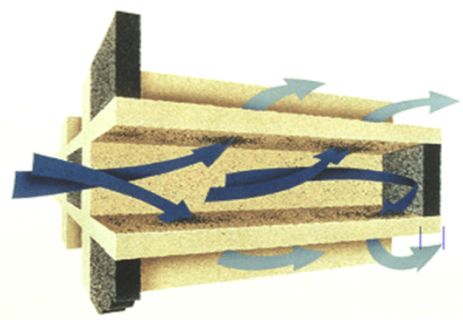

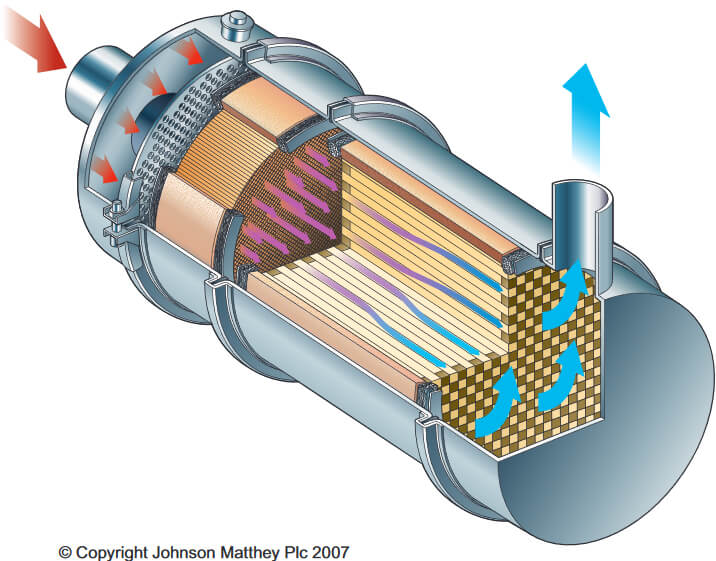

Both The Particulator® and the Johnson Matthey range of DPFs use ceramic wall flow filters. These are commonly used by truck and machine manufacturers on their new engines and are the most effective technology in reducing Diesel particulate from exhaust. The exhaust gas has to pass through the porous walls of many channels in the filter in order to exit the exhaust outlet. A very high filtration rate is achieved to remove nearly all the particulate by mass and size.

Johnson Matthey DPFs come in a wide range of filter sizes. The filter is sized to meet the back pressure requirements of the engine manufacturer at the maximum exhaust flow rate for that application. This assessment must also take into account the likely soot loading of the filter. Johnson Matthey have many years experience to draw on when selecting the correct filter size for a particular engine and application.

Although wall flow filter technology is very effective at taking Diesel particulate from exhaust, without regular regeneration the particulate would accumulate in the filter leading to higher exhaust back pressure and possible damage to the engine. That is why all DPF systems have some means of regenerating or cleaning the filter of its trapped particulate.

There are two types of regeneration possible, active, that requires the operator to initiate a regeneration cycle periodically, or passive, that uses catalysts to continuously burn the soot from the filter during normal engine operation. The active systems involve heating the filter to above the ignition temperature of the particulate so that it burns in air. Heating systems can be electrically powered or use Diesel fuel in a burner. Passive systems may use an exhaust catalyst in front of, or on the filter to generate NO2 that removes the particulate at lower temperatures, or a catalyst that is added to the fuel that promotes the burning of particulate with oxygen at lower temperatures.

The CRT®, a Johnson Matthey invention, is the most widely used passive device and uses a catalyst in front of the filter. Like all passive devices, the CRT® relies on certain exhaust temperatures being exceeded on a regular basis for the continuous regeneration mechanism to be successful. In the CCRT® the filter is also coated with catalyst to achieve regeneration at lower exhaust temperatures than needed for the CRT®. Fuel borne catalysts require quite hot exhaust temperatures to work successfully and can only be used in limited applications.

When selecting the best regeneration type for a particular application the preferred option is a passive system using the CRT® technology as this minimises input from the machine operator. Whether or not a passive system can give reliable regeneration and low build up of soot on the filter depends on a number of factors. The most important of these is exceeding a minimum exhaust temperature for a certain percentage of the operating time. This depends on how hard the engine is normally working and how close to the engine the filter can be fitted. For example, an excavator usually works hard and is often a good application for a passive system, whereas a crane will often only work hard intermittently and the engine is idling for prolonged periods and should generally not be fitted with a passive DPF. The NOx to PM ratio also needs to be considered before using a passive system as it relies on NOx to remove soot from the filter. The EU emissions level usually gives a good indication of this ratio. If the application is not considered suitable for a passive system, then the correct active system must be selected. The two main types use heating from electrical elements or from a Diesel burner. The electrical system requires an external power supply whereas the burner system uses fuel from the machine’s Diesel tank.

BISAF has developed a retrofit particulate filter to control the DPM emissions from smaller construction machines that, because of their size, are often used in confined spaces. Emissions legislation for small construction machines is not as tight as it is for the larger machines, resulting in particulate emissions many times higher. Even the Stage V legislation for construction machines, to be introduced in 2019, will not result in filters on these machines.

BISAF was also looking for a solution for the rental industry as many of these smaller machines are hired for specific jobs, some of which will require filters and some that will not. The filter that we have developed is called “The Particulator®” and uses OEM filter technology for almost complete removal of DPM. It also has a convenient electrical heating system that regenerates the filter in 30 minutes and can be fitted and removed from a machine in minutes.

BISAF is also the UK agent for Johnson Matthey’s range of retrofit Diesel Particulate filters for larger construction machinery. Johnson Matthey is a world leader in this DPF technology, supplying many of the car, truck and machine manufacturers around the world. They have been supplying retrofit filters for construction machines for 25 years and have developed a full range of sizes and regeneration types to be able to retrofit any engine in any non-road mobile machinery application.

Please contact our experts to select the best DPF for your application.